Begumpet ,Hyderabad

Begumpet ,Hyderabad

500 016, A.P, India.

Phone No : +91-40-2340 2682

Mobile : +91-9959000380

E-mail : info@conewafer.com

Note: Click on any link or the contact Image auto closes the panel.

Wafer Biscuit Equpiment

The forming of wafer biscuit is inseparably connected with the operation of the wafer oven.

The type of wafer biscuit commonly found is a cookie with top and bottom layers of characteristically crisp wafer sheets inclosing either one layer of creme or alternating layers of creme and wafer. The Wafer Biscuits are generally rectangular in form, but many other shapes are possible and there are many combinations of fillings and coatings which, in the most complex forms, resemble candy more than Biscuits. The equipment for ice cream cake cones and cups, hollow wafer sticks, fan wafers, shells, etc. appears considerably different, although the principles are the same.

The sequence of steps in a factory equipped to make this product is:

(1) Ingredients are mixed in whisks and the batter pumped to a supply tank.

(2) Batter is dispensed by an accurate measuring piston pump onto wafer plates at the entrance to an oven. The dispensing device travels with the "book" (a' pair of plates) while the latter is open and then withdraws and returns to its initial position as the plates close.

(3) After closes on the batter, the book continues to travel through the oven absorbing heat and cooking the batter.

(4) The baked wafer sheets are removed from their plates by take-off units and conveyed on a Conveyour to collection containers from which they are transferred to the wafer-builder equipment.

(5) At the filling applicator, creme from the filling mixers is spread on the wafer sheet, which is now at room temperature. Alternate layers of wafer and creme are built up until the required thickness of wafer is obtained.

(6) Completed sandwiches are passed through a pressing unit which causes the components to stick together.

(7) From the pressing unit, the sheets pass through a cooler which sets up the fillings.

(8) The sheets are collated into a stack of the required thickness and fed to the cutting machine to be sliced into individual biscuits.

(9) After slicing, the biscuits may be enrobed with chocolate or other fat based coating.

(10) The finished biscuits are packaged.

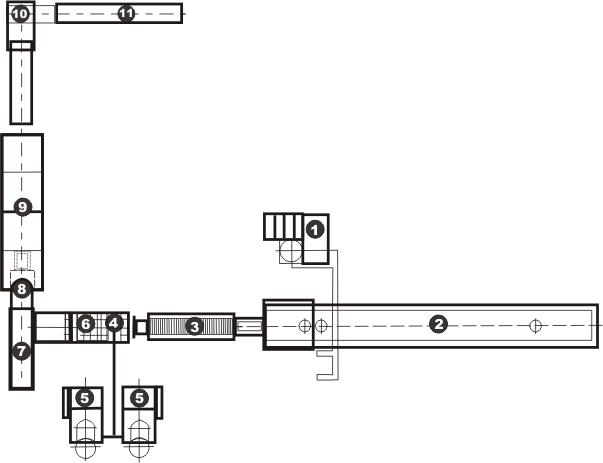

The layout for a fully, automatic wafer production line. Key to the numbered devices:

Click Here to See an animation of ZWA Wafer Plant Medium Layout Demo

Click Here to See an animation of WA-72 Wafer Plant Big Layout Demo Ovens made by different manufacturers can vary substantially in structural details. The oven described below represents a hypothetical model of relatively simple design incorporating all of the important operating functions.

In the traveling book ovens, sets of two plates each (sometimes called "Wafer tongs ") are mounted on wheels that support them on rails fixed on each side. A chain conveyor system pulIs the books continuously through an upper course, then through a lower course in the baking chamber. The bottom plate is fixed solidly to the carrier chains and the top plate is hinged to the bottom plate. Books open automatically at the urging of cams to accept their charge of batter, then close and lock together. The closed books containing batter are carried through the heated chamber. When it reaches the front of the oven, the book opens, the baked sheet is ejected by mechanical means perhaps assisted by an air blast. The book moves on to receive its next deposit of batter. Wafer ovens are made in standard models containing 12, 18, 24, upto 72 plates. Models with 36 plates, and perhaps even larger units, are also available, from some manufacturers on special order. The plates are typically 290 by 470mm in length and width, but there appears to be a trend toward larger, plates. Plates can either be mounted on frames or be self-supporting. Themain advantage of the latter is that they contact the flames directly. Also, they can be adjusted easier. A special gray cast iron has been recommended for the construction material. Hard chrome plating can be applied to extend cleaning cycles and promote release of the wafer from the baking surface. Oven books are cured by the application of vegetable or animal fat to heated plates, similar to the treatment used for other baking surfaces.

Production rates vary depending on several factors, including thickness of the sheet, type of batter, exent of baking (how much moisture is removed), etc.,

Wafer ovens can be heated by gas or electricity. When gas is used, the entire chamber is heated, while electrical heating is done by means of elements built into each plate.

The type of wafer biscuit commonly found is a cookie with top and bottom layers of characteristically crisp wafer sheets inclosing either one layer of creme or alternating layers of creme and wafer. The Wafer Biscuits are generally rectangular in form, but many other shapes are possible and there are many combinations of fillings and coatings which, in the most complex forms, resemble candy more than Biscuits. The equipment for ice cream cake cones and cups, hollow wafer sticks, fan wafers, shells, etc. appears considerably different, although the principles are the same.

The sequence of steps in a factory equipped to make this product is:

(1) Ingredients are mixed in whisks and the batter pumped to a supply tank.

(2) Batter is dispensed by an accurate measuring piston pump onto wafer plates at the entrance to an oven. The dispensing device travels with the "book" (a' pair of plates) while the latter is open and then withdraws and returns to its initial position as the plates close.

(3) After closes on the batter, the book continues to travel through the oven absorbing heat and cooking the batter.

(4) The baked wafer sheets are removed from their plates by take-off units and conveyed on a Conveyour to collection containers from which they are transferred to the wafer-builder equipment.

(5) At the filling applicator, creme from the filling mixers is spread on the wafer sheet, which is now at room temperature. Alternate layers of wafer and creme are built up until the required thickness of wafer is obtained.

(6) Completed sandwiches are passed through a pressing unit which causes the components to stick together.

(7) From the pressing unit, the sheets pass through a cooler which sets up the fillings.

(8) The sheets are collated into a stack of the required thickness and fed to the cutting machine to be sliced into individual biscuits.

(9) After slicing, the biscuits may be enrobed with chocolate or other fat based coating.

(10) The finished biscuits are packaged.

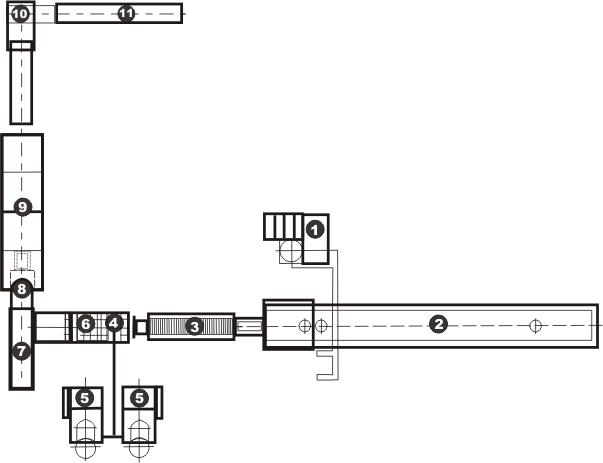

The layout for a fully, automatic wafer production line. Key to the numbered devices:

Click Here to See an animation of ZWA Wafer Plant Medium Layout Demo

Click Here to See an animation of WA-72 Wafer Plant Big Layout Demo Ovens made by different manufacturers can vary substantially in structural details. The oven described below represents a hypothetical model of relatively simple design incorporating all of the important operating functions.

In the traveling book ovens, sets of two plates each (sometimes called "Wafer tongs ") are mounted on wheels that support them on rails fixed on each side. A chain conveyor system pulIs the books continuously through an upper course, then through a lower course in the baking chamber. The bottom plate is fixed solidly to the carrier chains and the top plate is hinged to the bottom plate. Books open automatically at the urging of cams to accept their charge of batter, then close and lock together. The closed books containing batter are carried through the heated chamber. When it reaches the front of the oven, the book opens, the baked sheet is ejected by mechanical means perhaps assisted by an air blast. The book moves on to receive its next deposit of batter. Wafer ovens are made in standard models containing 12, 18, 24, upto 72 plates. Models with 36 plates, and perhaps even larger units, are also available, from some manufacturers on special order. The plates are typically 290 by 470mm in length and width, but there appears to be a trend toward larger, plates. Plates can either be mounted on frames or be self-supporting. Themain advantage of the latter is that they contact the flames directly. Also, they can be adjusted easier. A special gray cast iron has been recommended for the construction material. Hard chrome plating can be applied to extend cleaning cycles and promote release of the wafer from the baking surface. Oven books are cured by the application of vegetable or animal fat to heated plates, similar to the treatment used for other baking surfaces.

Production rates vary depending on several factors, including thickness of the sheet, type of batter, exent of baking (how much moisture is removed), etc.,

Wafer ovens can be heated by gas or electricity. When gas is used, the entire chamber is heated, while electrical heating is done by means of elements built into each plate.